Information

Substrates and Adhesion

Adhesives attach to the surfaces of two substrates, unlike

a process that fuses substrates into a unified whole such

as welding metal or solvent activation of plastics. In

selecting a 3M adhesive or tape, surface condition must

be considered: roughness, smoothness, porosity, coated,

uncoated, cleanliness, flexibility, size of the part and

surface energy of the part.

Adhesive paste, for example, flows readily into a rough

surface for improved effective adhesion. Flexible materials

such as paper or thin gauge metal can be bonded with a

thin adhesive transfer tape. Large rigid parts with smooth

clean surfaces can be bonded with a variety of 3M

products ranging from double coated foam tapes to two-

part structural adhesives. Some plastics have plasticisers

which migrate to the surface and degrade the bond over

time, so a plasticiser-resistant adhesive or tape is essential.

If the substrate has been powder coat painted, the coating

is the bonded surface rather than the substrate and you

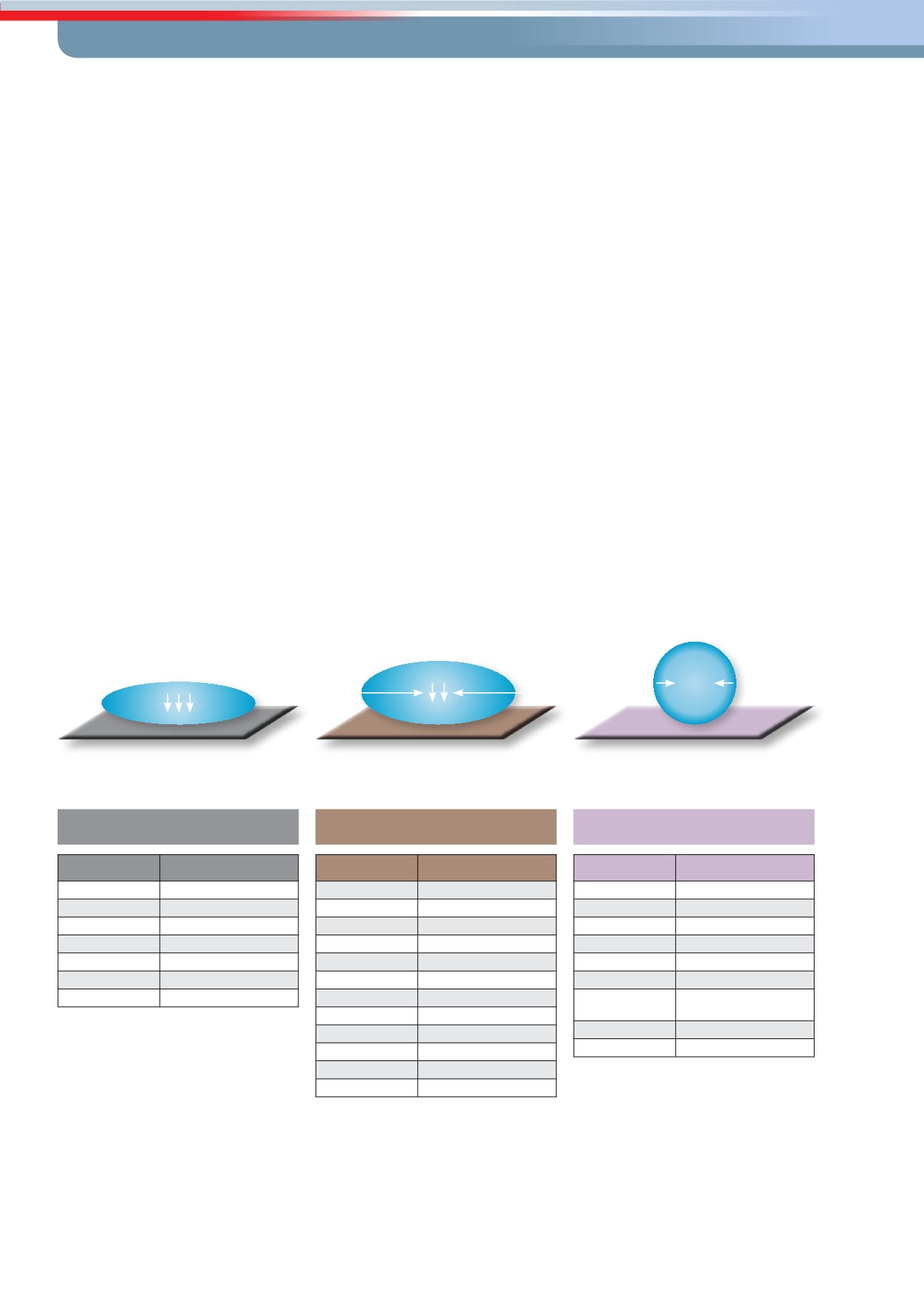

Metals

Surface Energy Dynes/cm

Copper

1103

Aluminium

840

Zinc

753

Tin

526

Lead

543

Glass Porcelain

250-500

Stainless Steel

700-1100

HSE Plastics

Surface Energy Dynes/cm

Phenolic

47

Nylon

46

Alkyd Enamel

45

Polyester

43

Epoxy Paint

43

Polyurethane

43

ABS

42

Polycarbonate

42

PVC Rigid

39

Noryl

38

Acrylic

38

Polane Paint

38

LSE Plastics

Surface Energy Dynes/cm

PVA

37

Polystyrene

36

Acetal

36

EVA

33

Polyethylene

31

Polypropylene

29

Polyvinyl Fluoride

Film

28

PTFE Fluoropolymer

18

Powder Coatings

**

** Broad range of surface energy

Metal Surfaces

HSE Plastics

LSE Plastics

would want to consider a 3M tape or adhesive developed

specifically for that surface.

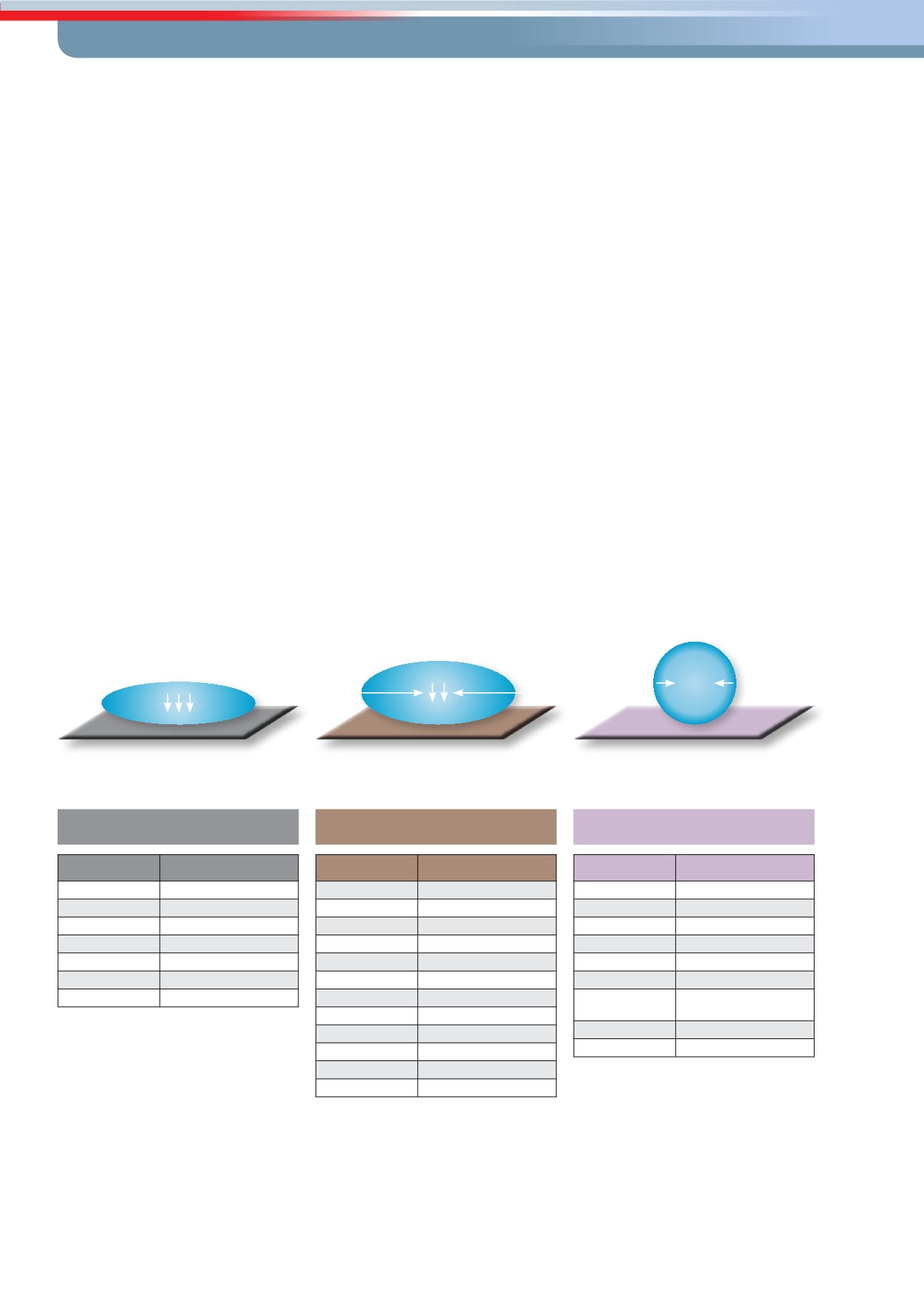

Surface energy ranges from high to low. To illustrate the

concept of surface energy, think of water on the unwaxed

bonnet of a car. The unwaxed bonnet has high surface

energy and water on the hood flows into puddles. In

comparison, a waxed hood has low surface energy and water

beads up rather than flows out. Similar to water, adhesive

on a high surface energy surface flows and “wets out” the

surface. “Wetting out” is required to form a strong bond.

As a rule of thumb, the higher the surface energy, the greater

the strength of adhesion.

Specially formulated adhesives are available for low surface

energy surfaces. The following illustrations and surface

rankings give you an idea of relative surface energy.

Regardless of surface energy, the substrate must be unified,

dry, and clean to maximise adhesive contact.

(High Surface Energy)

(High Surface Energy)

(Low Surface Energy)

28