3M

™

VHB

™

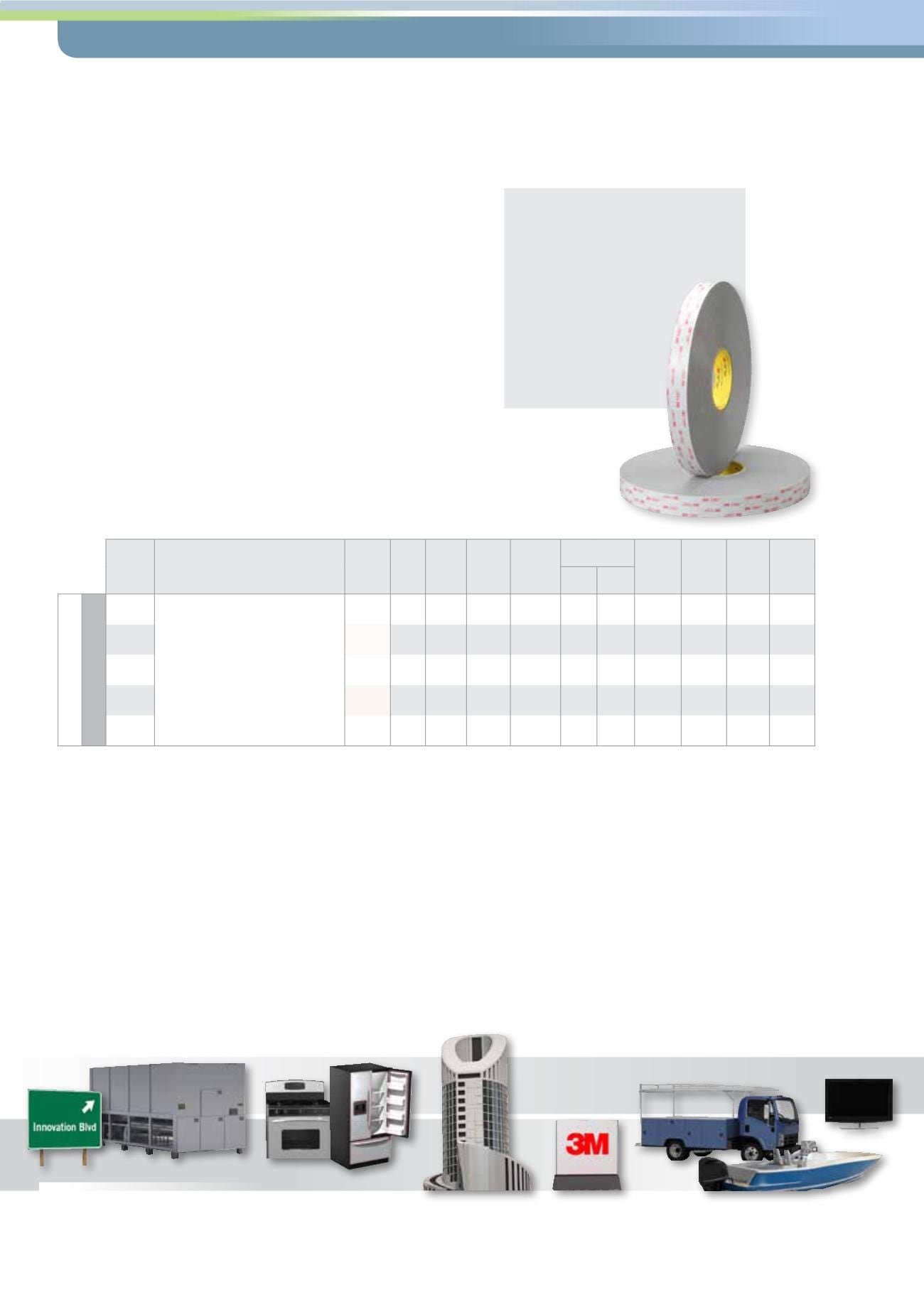

Tape RP Range

RP16, RP25, RP32, RP45, RP62

All Star Performance at a Competitive Price

All acrylic construction gives 3M™ VHB™ RP extraordinary

strength, conformability and versatility indoors and outdoors.

Available in the following thicknesses: 0.4mm, 0.6mm, 0.8mm,

1.1mm and 1.6mm.

Unlimited Design and Application Possibilities

The 3M™ VHB™ RP family is ideal for General Industrial,

Interior Fitout and Signage applications, and features a paper liner

for die cutting solutions. The 3M™ VHB™ RP family bonds to a

wide variety of surfaces

The 3M™ VHB™ RP family bonds to a

wide variety of surfaces, including:

• Glass

• Metal

• Many plastics

• Composites

• Sealed wood

• Painted surfaces

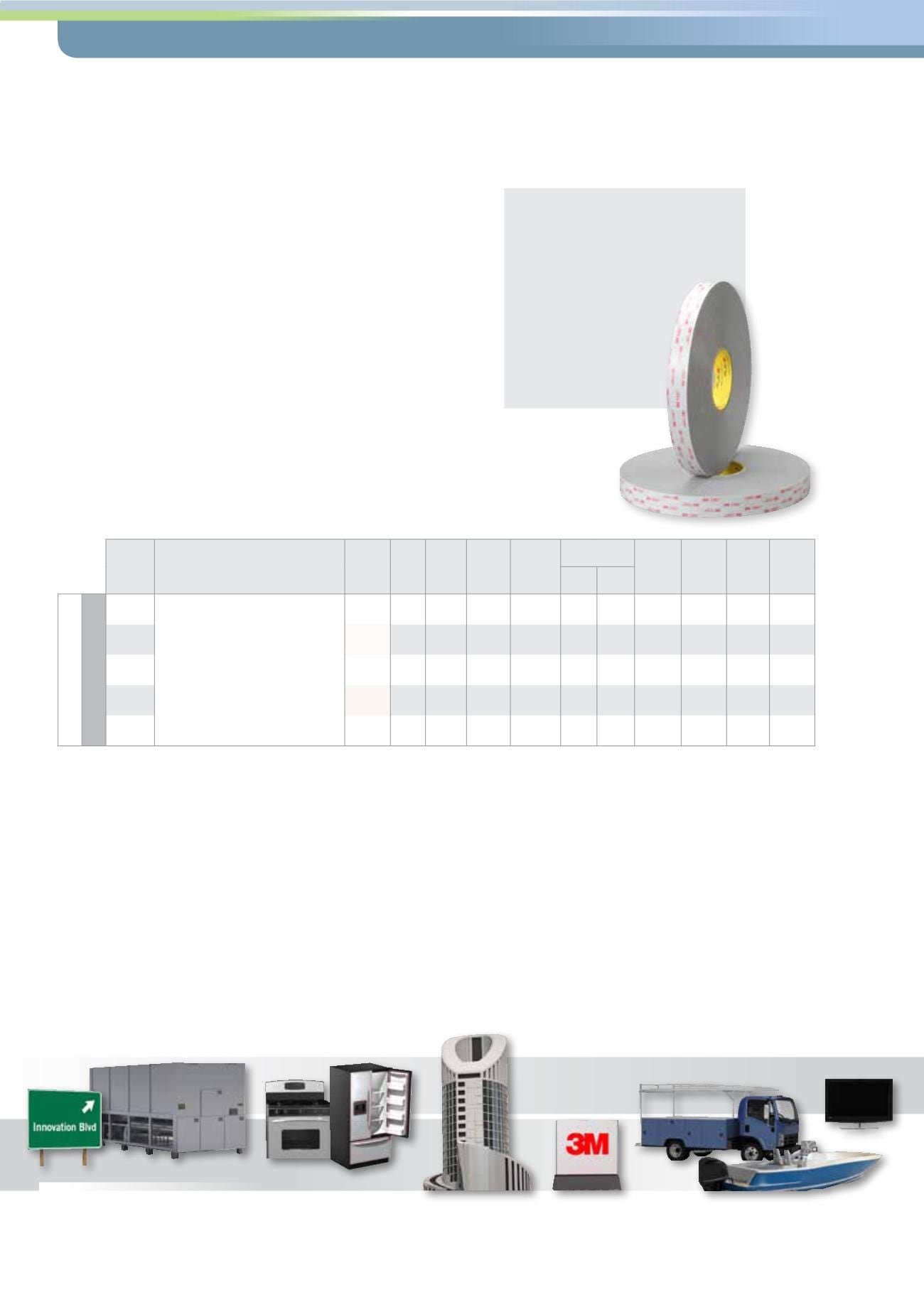

Product

Key Features

Thickness

(mm)

Colour

Acrylic

Adhesive

Type

1

Liner

Type

2

Solvent

Resistance

Temperature

Resistance

Plasticiser

resistance

Relative

adhesion

3

HSE (Metal,

Glass)

Relative

adhesion

3

HSE

(Plastics)

Relative

adhesion

3

LSE

(Plastics)

Hours

(

o

C)

Weeks

(

o

C)

General Purpose VHB

™

Tapes

Conformable Foam

RP16

The 3M VHB RP family is ideal for general industrial,

Interior Fitout and Signage applications, and features

a paper liner for die cutting solutions. All acrylic

construction gives 3M VHB RP excellent strength,

conformability and versatility indoors and outdoors.

Note: DK Paper liner not recommended for exterior

applications where liner is exposed to weather/

moisture for any prolonged period.

0.4

Grey MP

A

(printed)

High

121 93

Good

High

High Low

RP25

0.6

Grey MP

A

(printed)

High

121 93

Good

High

High Low

RP32

0.8

Grey MP

A

(printed)

HIgh

121 93

Good

High

High Low

RP45

1.1

Grey MP

A

(printed)

High

121 93

Good

High

High Low

RP62

1.5

Grey MP

A

(printed)

High

121 93

Good

High

High Low

1

MP - multi-purpose acrylic. ² Liner Types: A - 3 mil 54# Densified Kraft Paper.

3

Relative adhesion with substrate cleaning only. Note: - Adhesion and plasticiser resistance can be improved on some substrates with additional

surface preparation, such as abrasion and priming. Refer to Technical Bulletin for use of VHB tapes and recommended surface preparation.

Selecting the right 3M

™

VHB

™

Tape for your application is easy.

Factors to consider when choosing a 3M

™

VHB

™

tape:

1.

What are you bonding together?

2.

What performance demands are there?

3.

What kind of environmental conditions will the finished product be subject to?

3M

™

Bonding Tapes

20