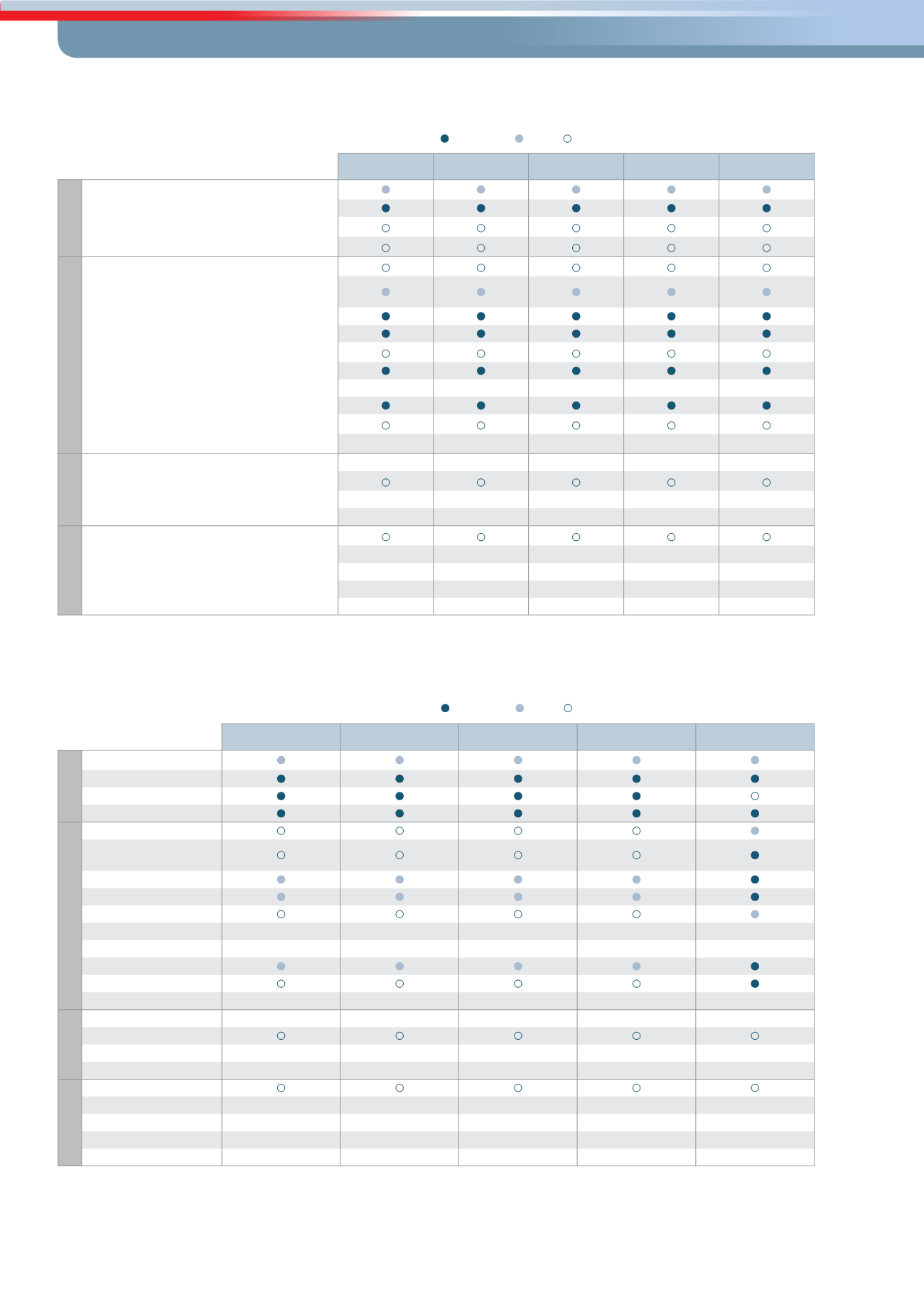

Substrates

4004

4008

4016

4032

4085

Glass & Metal

Glass & Ceramics, Polished Stone

Bare Aluminium

Brass/Copper

Bare Steel

Plastic

Low Surface Energy (PP - PS)

Medium Surface Energy

(Acrylic - ABS)

High Surface Energy (PC - PU)

FRP

Nylon

Flexible Vinyl

–

–

–

–

–

Polyurethane Foam

–

–

–

–

–

Painted Surface (PU, Acrylic)

Painted Surface (Powdercoat)

Expanded Polystyrene Foam (EPS)

–

–

–

–

–

Rubber

EPDM

–

–

–

–

–

Neoprene , Natural Rubber

Santoprene

–

–

–

–

–

Silicone Rubber

–

–

–

–

–

Other

Wood

Leather

–

–

–

–

–

Fabric

–

–

–

–

–

Paper / Cardboard

–

–

–

–

–

Glass wool Insulation

–

–

–

–

–

3M

™

VHB

™

Tapes - RP Range

3M

™

Double Coated Urethane Foam Tapes

Best Choice

Good

Special surface preparation required

–

Not recommended

Best Choice

Good

Special surface preparation required

–

Not recommended

IMPORTANT NOTE: These tables describe the relative adhesion to the listed surface within the product group, you may need to take into consideration factors such as:

Gap filling, ultimate joint strength, joint flexibility or joint thickness, environmental resistance, small or large surface area coverage, application methods, positioning time or cure time.

Please refer to individual product technical datasheets for more complete details of typical product performance.

The technical information and data on these pages should be considered representative or typical only and should not be used for specification purposes. Refer to Technical Data Sheets for specific perfomance measures and

surface preparation requirements. For further assistance contact 3M.

Final product selection should be made only after evaluation of sample bonds.

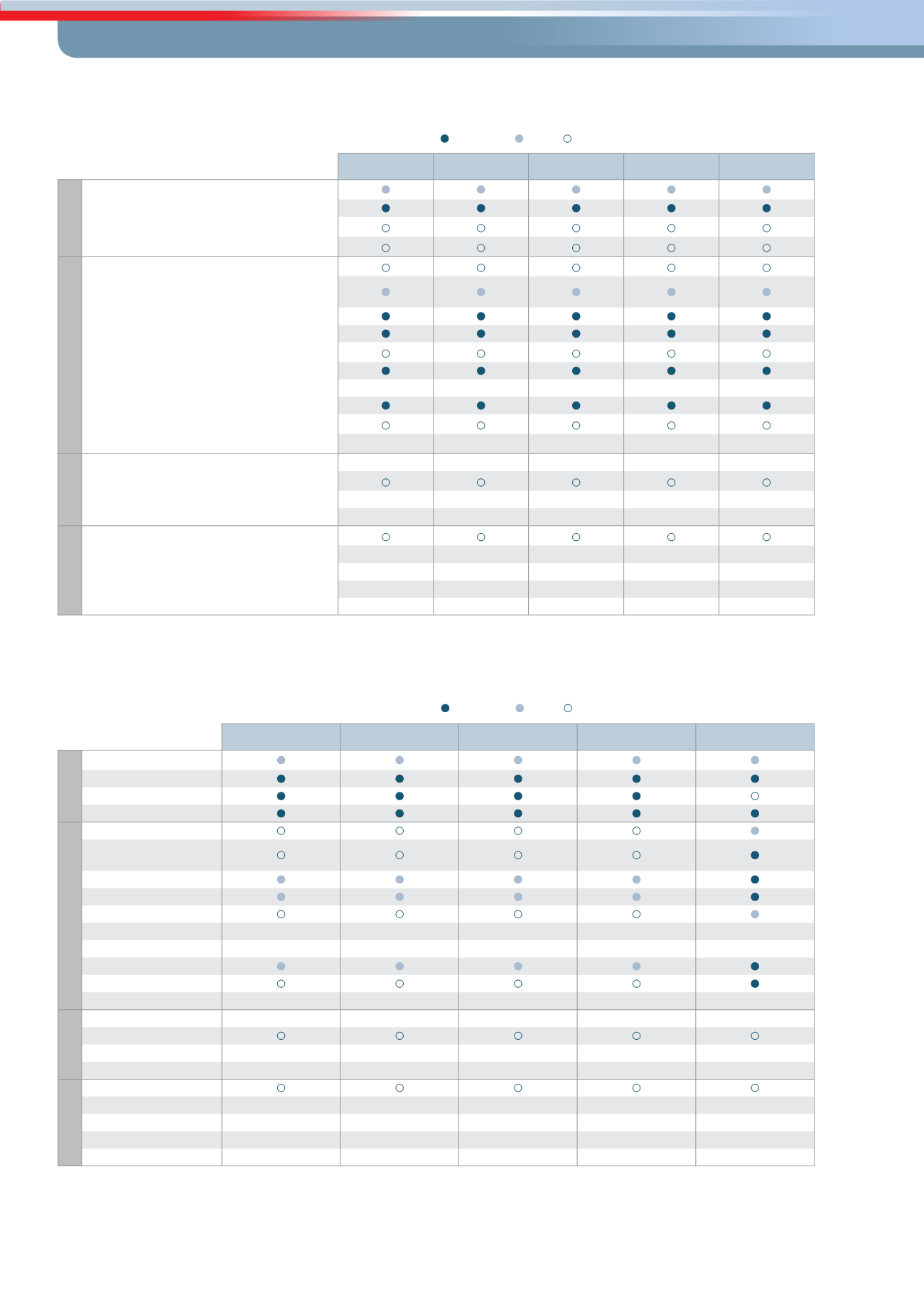

RP16

RP25

RP32

RP45

RP62

Glass & Metal

Glass & Ceramics, Polished Stone

Bare Aluminium

Brass/Copper

Bare Steel

Plastic

Low Surface Energy (PP - PS)

Medium Surface Energy

(Acrylic - ABS)

High Surface Energy (PC - PU)

FRP

Nylon

Flexible Vinyl

Polyurethane Foam

–

–

–

–

–

Painted Surface (PU, Acrylic)

Painted Surface (Powdercoat)

Expanded Polystyrene Foam (EPS)

Rubber

EPDM

–

–

–

–

–

Neoprene , Natural Rubber

Santoprene

–

–

–

–

–

Silicone Rubber

–

–

–

–

–

Other

Wood

Leather

–

–

–

–

–

Fabric

–

–

–

–

–

Paper / Cardboard

–

–

–

–

–

Glass wool insulation

–

–

–

–

–

IMPORTANT NOTE: These tables describe the relative adhesion to the listed surface within the product group, you may need to take into consideration factors such as: Gap filling, ultimate joint strength, joint flexibility or joint

thickness, environmental resistance, small or large surface area coverage, application methods, positioning time or cure time. Please refer to individual product technical datasheets for more complete details of typical product

performance.The technical information and data on these pages should be considered representative or typical only and should not be used for specification purposes. Refer to Technical Data Sheets for specific perfomance

measures and surface preparation requirements. For further assistance contact 3M. Final product selection should be made only after evaluation of sample bonds.

Minimum surface preparation for glass is to clean with 3M™ AP-115. Please refer to the 3M™ VHB™ Surface Preparation Guide - adhesion to most surfaces can be improved with some surface preparation.

34