-

All floor pads are not created equally, a formula for sustainability.

July 10, 2019

All floor pads are not created equally, a formula for sustainability.

Using the right tools to do the right job is common sense advice that applies to a wide range of applications. It not only ensures a job well done, as the right tools are critical to achieving an effective result, it also serves to increase productivity and leads to cost savings. The same principles apply to floor care, maintaining clean, safe and beautiful floors is an ongoing challenge that requires a commitment to excellence. Whether you need to strip, clean or polish your flooring, one of the most important elements in floor care are floor pads.

“It is essential to have good tools, but it is also essential that the tools should be used in the right way.”

-- Wallace D. Wattles --Floor pads...the basics.

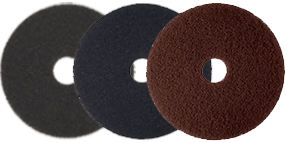

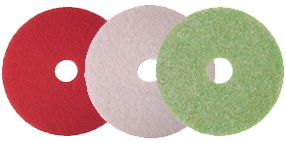

A lot has changed with floor pads over the years, with the industry evolving from a handful of products to hundreds of different options that can confuse even a seasoned professional. From a broad perspective floor pads can be categorised into the following applications:

Stripping pads

It is vital to strip your floor thoroughly before protecting it with floor finish to ensure that you obtain the desired results.

Scrubbing pads

Scrubbing pads are designed for effective and consistent routine maintenance of protected and unprotected floors to remove black marks and dirt before raising the shine or just to keep your unprotected floor in good shape.

Burnishing pads

Also known as polishing pads are designed to produce shine on a newly coated floor and restore the gloss of protected floors.

There are three main components in a floor pad:

- Fibre - this element is the backbone of the pad, depending on the manufacturer, there are different types of fibre used in floor pads and all fibres wear differently. An open fibre construction is preferable as it reduces clogging during use allowing the pad to pick up more dirt and grime for a more effective job.

- Abrasive - there is an abrasive mineral used in making floor pads and this mineral is what enables the pads to clean the floor.

- Resin - there is an adhesive resin that holds the mineral onto the fibre.

These three components work hand in hand when the spinning pad comes into contact with the floor, with each element playing a significant role in the cleaning process. The importance of the adhesive resin in holding the abrasive mineral to the fibre is critical if any of those elements - the abrasive, the adhesive or the fibre is unable to withstand the constant spinning on the floor, the pad will not function well. In simple terms the mineral needs to stay whole, the resin needs to keep the mineral in place and the fibre needs to hold together.

As you begin to add the variables of different cleaning solutions, the coatings, it becomes even more important to have floor pads constructed of high-quality materials that will hold up and go the distance and not dissolve or fall apart. More often than not the adhesive resin on poor quality floor pads dissolve when chemicals, particularly stripper, is applied and the abrasive minerals actually fall off the pad resulting in inferior work and floors needing to be re-stripped. The supplementary expense of using high-quality pads far outweigh the additional cost, time and effort involved in any potential re-work due to an inferior pad not performing and getting the job done as expected.

What makes a good floor pad?

Understanding this difference will help you make the best decision for your specific need and will help you get the best value for your money.

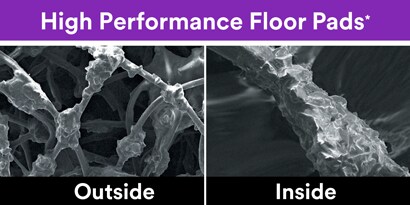

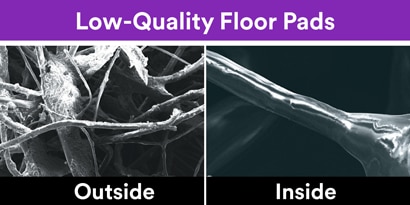

Product performance - In a high-quality floor pad, the abrasive minerals are consistent throughout the entire pad, not just on the initial cleaning surface of the pad. So if you were to slice a high-quality pad in half horizontally, you would see that the amount and density of the abrasive mineral are exactly the same in the centre of the pad as it is on the outsides of the pad. This is important because as the pad wears down, new fibres are being exposed and these new fibres have exactly the same abrasive qualities as the old fibres that were worn away. This ensures that as the pad wears, the cleaning, shining and/or stripping capabilities of the pad remain consistent for the entire life of the pad. Low-quality less expensive pads are not constructed in this manner. They do not have the same density of abrasive material on the inside as they do on the outside, so as these pads wear, the amount of exposed abrasive decreases and the ability of the pad to do its job also decreases. Refer to the microscopic diagrams below to see the difference between high performance and low-quality floor pads.

- Fibres uniformly coated with resin and mineral throughout entire pad, producing more consistent results

- Combination of highly conformable fibres help to maximise the pad-to-floor contact

- Fibres randomly coated with resin and mineral, which can produce inconsistent results

- Larger fibres are less conformable, providing fewer contact points with the floor

Sustainability - Floor care is one of the most important cleaning tasks in any facility care routine. However, the daily and ongoing use of floor pads can ultimately lead to a large amount of waste, causing a negative impact on the environment. With sustainability becoming an increasingly important goal for companies all over the world, selecting the right products can make the whole process greener and help facility managers meet their sustainability goals. Just as floor pads differ in quality, they can also differ in how environmentally friendly they are. As a result, it’s important to choose floor pads that are durable and high-performing in order to extend the life of the pad and reduce the amount of waste that ends up in a landfill. Products with sustainable profiles can be a great addition to any cleaning program, using products that are third-party certified ensures they live up to their sustainability claims minimising their impact on the environment.

3M Floor Pads receive Green Seal Certification

Green Seal Certification is a process that ensures that a product or service meets rigorous performance, health, and environmental criteria. Green Seal is a non-profit environmental standard development and certification organisation. Its flagship program is the certification of products, services, restaurants, and hotels. Certification is based on Green Seal standards, which contain performance, health, and sustainability criteria. Green Seal® takes the guesswork out of identifying proven-safer options with guaranteed performance.

Green Seal is excited to recognise floor pads from 3M under the Environmental Innovation standard. These floor pads are a great example of a product innovation that achieves the triple bottom line - providing life-cycle impact reduction and environmental benefits without sacrificing product quality and efficiency.”

-- Doug Gatlin, Green Seal’s Chief Executive Officer --Having revolutionised floor maintenance more than 60 years ago with the invention of the world’s first synthetic non-woven floor pads, 3M have a wide range of floor pads for just about every task, as well as Green Seal certified pads to meet your sustainability goals. Several of 3M’s floor pads have been recognised by Green Seal’s Environmental Innovation program as products that significantly reduce environmental impact through product innovation, having received Green Seal’s Certification of Environmental Innovation under the GS-20 standard. 3M floor pads achieved certification based on a design for significantly improved performance, durability, or both, extending the useful life of the floor pad and reducing solid waste generation.

Sustainability is at the core of our product development, and all of our floor pads have at least one key sustainability attribute. From the raw materials that go into the pads to the composition of our packaging, we pay close attention to the entire life-cycle of the product in an effort to reduce its environmental impact. The environmental benefits that floor pads from 3M provide include:

- Floor pads from 3M have improved function at initial use and mid-life, and improved durability, meaning they get the job done faster or require fewer pads to get the job done over time.

- Many floor pads by 3M are produced in a “zero-landfill” facility, resulting in less waste in landfills. Additionally, the waste created during the manufacturing process is reused or recycled.

- Many floor pads by 3M are produced using water-based resins or contain at least 50 percent post-consumer recycled materials.

- Our packaging is 100% recyclable and made with 50-100% recycled content.

Green Seal’s Environmental Innovation Standard evaluation of product innovation includes two major steps – a comparison of the product to mainstream offerings that provide the same function, and third-party verification that the product innovation delivers environmental impact reduction. In addition, the product innovation is considered against any major trade-offs that may occur to ensure net environmental benefit.

To learn more about 3M Floor Pads Contact a 3M Facility Safety Specialist for more information, we have floor and technical specialists that are available to assist, or visit www.3m.com/floorpads.

For more information on choosing the right floor pad for the job download our 3M floor pad selection guide.