-

Confined space...a death trap in waiting.

November 20, 2019

Confined space...a death trap in waiting.

Confined spaces present some of the most challenging working environments. From potentially toxic atmospheres to physically hazardous conditions such as extreme temperatures, unstable materials, or the potential for falls, confined spaces often present unseen challenges and can be a death trap in waiting. Not all employers and operators understand what constitutes a “confined space”, nor the dangers associated with working in such environments. Similarly, should the need for rescue from a confined space occur, a well prepared and rehearsed retrieval operation must be available for immediate implementation. The failure of understanding of confined space operations and rescue and retrieval methods can place both the employee and the employer at significant risk.

What is a Confined Space?

Confined spaces occur across almost all industries and workplaces, from agriculture to food and beverage, petrochemicals to construction and maintenance, water treatment and sewers to transportation and shipping. So precisely what is a confined space? Although confined spaces are not all defined in the same fashion around the globe, there is common ground to most of the various definitions for them. A confined space is an enclosed location that is not intended for human occupancy and may include a restricted means of entry or exit. If the space is partially or fully enclosed and may contain a hazard, or working within it creates a risk to your health or safety, then the area may be classified as a confined space.

Generally speaking, a confined space is a partially or fully enclosed space which contains the following characteristics:

“Confined space accidents are notorious for multiple casualties, with the largest risks coming from the injury and subsequent recovery of people from the space.”- Large enough for a worker to enter and perform work

- May have limitations to the entry to or exit from the confined space

- Is not designed for continuous human occupancy

- The provision of emergency response services is compromised

- May knowingly or unknowingly contain a hazardous atmosphere

- May contain other hazards that expose anybody in the area to risk

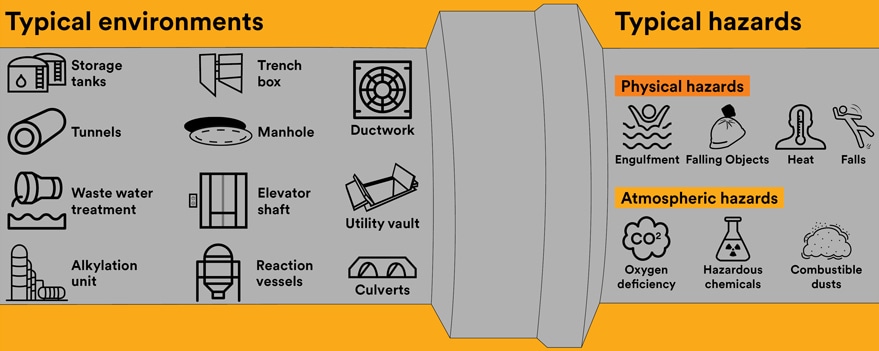

The following are some examples of confined spaces typically found in many industries:

- Tanks, vessels, silos and vats

- Manholes, pipes, culverts and ducts

- Large vessels, tanks and rooms with restricted entry and exit

- An enclosed area that may have a build-up of toxic or hazardous substances

Confined space activity is a complicated issue requiring expert analysis. It is not only the size of the space that is critical, or the ease of access and egress, or the risk of hazardous atmospheres and chemicals within the confined space. It is a combination of all these coupled with the risk of injury and the resulting complexities for a rescue and recovery operation in this environment.

Why are Confined Spaces dangerous?

Confined space accidents are notorious for multiple casualties, with the largest risks coming from the injury and subsequent recovery of people from the space. Atmospheric hazards from the presence of chemicals are often odourless, tasteless and colourless. Lack of sufficient oxygen to remain conscious is also undetectable without the use of correctly calibrated analysis equipment. Restricted working space often leads to the work being carried out closer than desirable to electrical and mechanical risks, including moving machinery such as conveyors.

When accidents occur within confined spaces rescue measures are often initiated with untrained employees and inadequate equipment, in an unplanned and unrehearsed fashion. Ultimately risking the lives of the rescuers, who often succumb to the same fate as those they are attempting to rescue.

Confined space risks include:

- Oxygen deficiency

- Noxious and poisonous gases

- Suffocation by materials (e.g. grain silo) or drowning (e.g. culvert)

- Contact with toxic or hazardous materials (e.g. chemical industry)

- Electrocution

- Extremes of temperature (e.g. furnaces, cold rooms)

- Slips, trips and falls (e.g. descending /ascending access)

- Struck by falling objects

- Explosion

The image below provides a graphical summary of typical confined space environments and hazards.

How do we prepare for confined space operations?

Potential confined space operations are to be the subject of the same analysis as any other work practice where risks to employees are identified. Where the requirement exists for service or maintenance works in a confined space, the basic principles of hazard identification and risk assessment should be applied. The hierarchy of this process is as follows:

- Hazard identification

- Risk assessment

- Risk elimination

- Risk minimisation

- Protective equipment and work practice specification

Having identified confined space access as a hazard; the first objective is to eliminate the danger by changing the equipment or the work practice, thereby preventing the need for personnel to enter the confined space. Where this is not possible, risk minimisation action should be attempted, again by effecting changes to the equipment or work practice. For example; increasing the size of the entry and exit positions to the confined space, improving airflow and lighting, and isolating potential electrical and chemical hazards through the use of zone and process flow shutdowns using the correct lockout and tag out controls and processes.

If the results of the elimination and minimisation activities still leave an identified danger, efforts must then be directed at risk minimisation through the use of appropriate safety equipment and documented work practices covering the total confined space activity plan. These documented processes should comprise the original work required, but must also incorporate rescue and retrieval procedures in the event of an accident.

Taking the above into consideration, it is helpful to walk through each of the four principal elements to successfully manage and plan for work in confined spaces. The elements can be summarised as follows:

- 1. Plan – evaluate, document and plan for confined space entries on your site

- 2. Access – what you need to access a specific confined space, including a hazard assessment

- 3. Work inside – provide the appropriate personal protective equipment to protect the worker from both seen and unseen hazards

- 4. Rescue/retrieval – be prepared

Working safely in confined spaces.

Depending on the risk assessment conducted and the consideration of the four elements to manage and plan for confined space work, some or all of the following equipment may be required before, during and after the confined space access:

Access Equipment

Access to the confined space requires both the correct equipment and work practice which is usually achieved by the use of correctly matched equipment. Entry, exit and retrieval equipment provides a safe means of entrance and egress from a confined space, and for the provision of rescue and retrieval should it be required.

Oxygen analysis equipment

Oxygen analysis equipment to ensure adequate oxygen levels to support breathing, but not high enough levels that may intensify any fire risks. Depending on the risk analysis, this equipment may require being either a single sample or continuous monitoring.

Gas analysis equipment

Gas analysis equipment to detect hazardous levels of other gases or noxious fumes that may, or could become, present in the confined space.

Respiratory equipment

The oxygen and gas analysis results may then require the use of respiratory equipment which can range from full self-contained breathing apparatus, through airline flow equipment to simpler respirators. There are also ranges of respirators suitable for use in dust and atmospheres containing particulate matter.

Communication equipment

Communication equipment may also be required in confined space applications to maintain voice contact with the remote working personnel.

Training

As with any specialist equipment for use in hazardous environments, correct certified training in its use is highly recommended. Critical to the use of this equipment is professional confined space training and personnel certification, together with documented work practices that include rescue and retrieval plans.

Your partner in confined space safety.

Providing a safe means for workers to access and work in all types of confined space applications can be challenging. There is a lot to consider when it comes to planning for, working in, and rescuing someone from inside a confined space. Along with the diverse range of PPE, fall protection and gas detection products and resources that can help keep your workers safe when working in confined spaces, the highly trained professionals at 3M educate, train and provide extensive long-term support to ensure that all aspects of your confined space program are successful.

For more information on confined space safety, training and relevant products download our Confined Space Safety Solutions Catalogue.

Confined Space Safety

Solutions CatalogueProper planning is essential to working safely in confined spaces, if you need help choosing the right confined space safety equipment or to identify appropriate training for your needs, reach out to a 3M Safety Specialist.