-

Toolbox talks...do they really matter?

July 25, 2019

Toolbox talks...do they really matter?

As the bustling construction site came to life, work commenced for yet another busy day with the multitude of trades working to bring the industrial complex to life. The smell of coffee and cigarette smoke lingered in the air as the chatter from the workmen started to dwindle and the sound of power tools filled the air. It was a brisk winters morning, the wind was blowing, unexpectedly the skies began to shoot large and sporadic drops of rain that landed with a thud on the mixture of gravel and dirt beneath the foreman’s boots. As he headed up the scaffold the skies opened up and the rain became heavier and heavier. A downpour was upon the site when a call came through over the two-way radio, “John, secure the site.” As the foreman made his way along the scaffold to gather the tools, he slipped on the wet metal, as he fell the scaffold handrail broke his fall and he managed to regain his footing. Unfortunately, however, John had inadvertently pushed a hammer causing it to fall off the scaffold due to a missing toe board, falling 10 metres to the ground below, critically injuring a fellow worker whose hard hat had fallen off, apparently he wasn’t using his chin strap.

With the ambulance long gone and the site shut down, the inspector quizzing the foreman received a call, it was the hospital. “Good news John,” he said, “young Steve is going to pull through, he is lucky to be alive.” As the inspector left he turned and asked, “Was this Steve’s first week on site?” “Yes,” I replied. “How often do you have toolbox talks?” he asked sternly. “Every couple of weeks,” I responded with hesitation. “Hmm, maybe if you had them daily the issue of the missing toe board, untethered tools and Steve not using his chin strap may have come up, and we could have avoided this whole bloody mess. You know, toolbox talks don’t really take that long to conduct on a daily basis.”

So exactly what is a toolbox talk?

Employers, businesses, or anyone who is identified as a ‘person conducting a business or undertaking’ (PCBU), have legal obligations under worker health and safety laws to consult with employees when they are likely to be or are directly affected by conditions involving their health and safety. Workers also have the right and need the opportunity to express their opinions and be instrumental in any decisions relating to their health and safety. The best avenue for these consultations are toolbox talks.

A toolbox talk is an informal safety meeting that is focussed on safety-related topics that are specific to the job and/or workplace. Meetings are generally short and sharp lasting approximately 10-15 minutes and conducted on site, usually prior to the start of a job or shift to refresh and reinforce a workers knowledge on workplace hazards and safe work practices, while promoting a safety culture by transforming workplace safety into a daily habit. They typically cover (but are not limited to):

- Last minute safety checks

- The opportunity to openly exchange information

- Hazard identification

- PPE refresher training

- Addressing current safety issues and concerns

- Accident prevention

“The future of the safety movement is not so much dependent upon the invention of safety devices as on the improvement of methods of educating people to the ideal of caution and safety.”

- - Walter Dill Scott - -According to the International Labour Organization, every day, people die as a result of occupational accidents or work-related diseases – more than 2.78 million deaths per year. Additionally, there are some 374 million non-fatal work-related injuries each year, resulting in more than 4 days of absences from work. The human cost of this daily adversity is vast and the economic burden of poor occupational safety and health practices is estimated at 3.94 per cent of global Gross Domestic Product each year...yes, toolbox talks do matter and need to be taken seriously, studies have shown that the majority of accidents and injuries on the job can be minimised when everyone knows how to do their job safely.

Toolbox talks are the ideal medium to promote safe work practices and should form part of an organisation’s overall safety program. Although these talks are mostly associated with the construction industry, every organisation, large or small needs to talk about safety. Their outcomes provide company-wide benefits, from increased safety awareness and culture, a decrease in injuries and lost time, as well as increases in productivity in a safe and efficient manner. This not only improves a worker’s quality of life but ensures everyone arrives home safely at the end of the day. It’s about encouraging worker participation, engagement and creating a sense of ownership to challenge the mistaken belief that health and safety is solely the responsibility of the OH&S manager.

Tips for running a successful toolbox talk.

At 3M we understand that communicating health and safety can at times be difficult as resources are increasingly stretched, and time is tight. However, the importance of these safety meetings cannot be overlooked. Toolbox talks don’t have to be complicated, if you’re unsure where to start or not sure what topics to cover, we are here to help. 3M has developed a toolbox talk program called SafeTea Toolbox to help health and safety professionals engage their workforce in a discussion about health and safety and instil a sense of ownership in a way that is both effective and easy to manage, to make every workplace safer, by:

- Tackling worker complacency

- Building a positive safety culture

- Delivering engaging health & safety communications

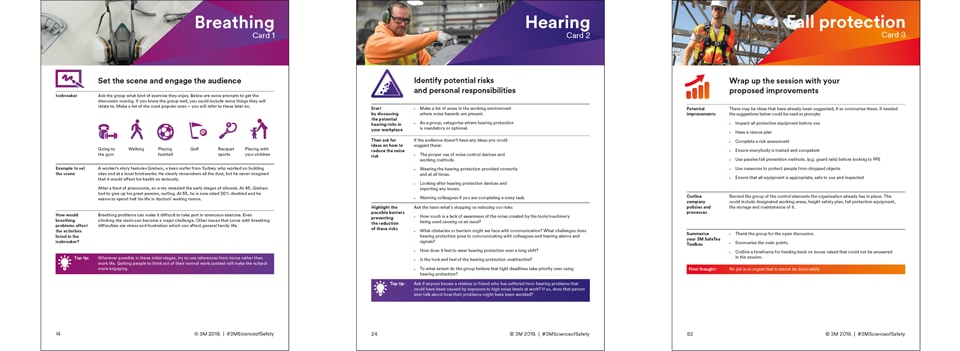

So how does the SafeTea Toolbox work? The 3M SafeTea Toolbox is available to download and provides a tool kit for engaging with employees, providing open questions, ice breakers and thought-provoking examples to present in a break out/tea-break session commonly known as the toolbox talk, with a view to generating debate across health and safety topics. Complete with ten modules, the first module provides a comprehensive introductory overview on how to conduct a successful toolbox talk that walks you through preparation, delivery and how to turn feedback into an action plan. The remaining nine modules cover key common health and safety risks and concerns to be used as topics for sessions revolving around:

- Breathing

- Hearing

- Touch

- Skin

- Muscles,bones and joints

- Wellbeing

- Think for 30 seconds

- Slips and trips

- Fall protection

- Section 1: Set the scene and engage the audience

- Section 2: Discuss potential risks and how the workforce can protect themselves and their colleagues

- Section 3: Company controls, summary and next steps

Each toolbox talk module outlined above is split into three sections and walks you through how to prepare, deliver, complete feedback and create actions for each individual topic.

The SafeTea Toolbox aims to increase understanding of the risks and consequences of non-compliance and ultimately drive a useful action plan for your workplace. Contact a 3M Safety Specialist for more information or explore our Science of Safety Podcast ... you’re sure to find useful information that can be incorporated into your toolbox talks. While you are there, why not subscribe to our 3M Science of Safety Newsletter to receive periodic safety news by email, including product information and promotions, regulatory updates, and training opportunities.